You’re staring at your worn, cracked concrete driveway or patio and wondering if there’s a simpler solution than tearing everything out and starting from scratch. The idea of pouring new concrete directly over the old surface is tempting—it sounds easier, faster, and potentially less expensive than complete removal and replacement.

But is it actually a viable option? Will the new concrete adhere properly? How long will it last? Understanding when this approach works, when it fails, and what alternatives exist can save you from making a mistake.

Before deciding whether to overlay existing concrete or opt for complete replacement, consulting with an experienced Concrete contractor in Michigan can help you evaluate your specific situation and determine the most cost-effective, long-lasting solution for your property.

When Pouring Over Existing Concrete Works

The Basic Requirements

Yes, you can pour concrete over existing concrete—but only under specific conditions. The existing concrete must be structurally sound with no significant cracking, spalling, or settlement issues. The surface should be relatively level without major height variations. There must be adequate drainage to prevent water from pooling under or around the new layer. And critically, you need sufficient clearance to add thickness without creating problems with doorways, garage entries, or other transitions.

When these conditions are met, a concrete overlay can be a practical solution that extends the life of your surface at a fraction of the cost of complete replacement.

Ideal Overlay Scenarios

Concrete overlays work best in certain situations. If your existing concrete has only surface-level cosmetic issues like minor staining, light surface cracking (hairline cracks), or an outdated appearance, an overlay can provide a fresh new surface. Overlays are also excellent for adding a decorative finish to plain concrete—you can stamp, stain, or texture the new layer to dramatically upgrade the appearance.

Indoor applications like basement floors or garage floors are particularly well-suited to overlays because they’re protected from weather extremes and freeze-thaw cycles that can compromise the bond between layers.

When You Shouldn’t Overlay Existing Concrete

Structural Problems

If your existing concrete has significant structural issues, an overlay simply masks problems without solving them. Major cracks wider than 1/4 inch will telegraph through to the new surface over time. Areas that have settled or heaved create an unstable base for new concrete. Spalling or flaking concrete indicates internal deterioration that will continue affecting any overlay. Damaged or exposed rebar suggests a structural compromise that an overlay cannot fix.

In these situations, the overlay will likely fail prematurely, wasting your money and necessitating complete replacement anyway.

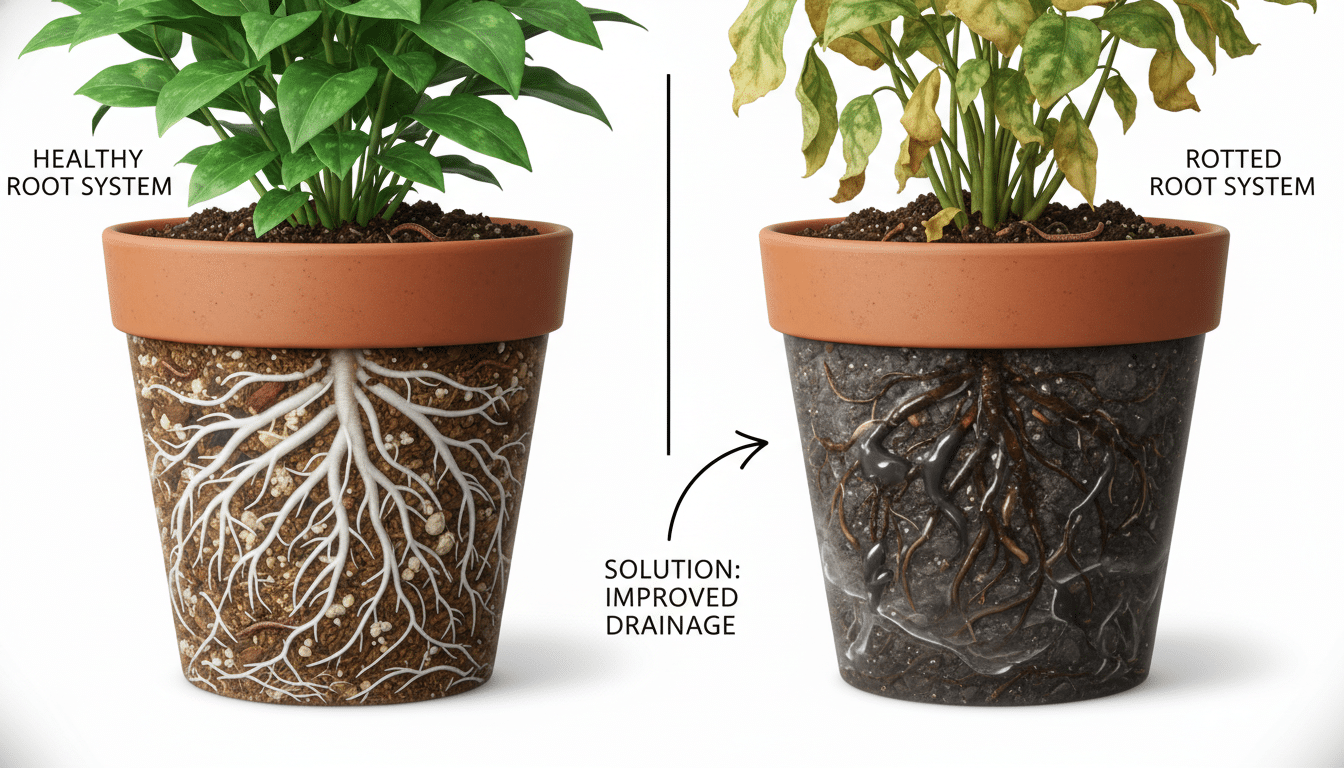

Drainage Issues

Concrete that shows signs of chronic drainage problems—standing water, efflorescence (white mineral deposits), or water staining—shouldn’t receive an overlay until drainage is corrected. Adding another layer of concrete without addressing the underlying water issue simply creates a new surface that will experience the same problems.

Insufficient Height Clearance

Adding even a thin concrete overlay raises the surface level. If your existing concrete meets garage doors, doorways, or other structures with minimal clearance, raising the level can create functional problems. You might not be able to close doors properly, create awkward transitions, or violate building codes regarding step heights.

How Concrete Overlays Are Properly Installed

Surface Preparation Is Critical

The most important factor in overlay success is thorough surface preparation. The existing concrete must be cleaned completely to remove dirt, oil, paint, sealers, and any contamination that would prevent bonding. Power washing, grinding, or shot blasting creates the clean, rough surface texture necessary for proper adhesion.

Any cracks must be properly repaired before overlay installation. Small cracks can be filled with epoxy or polyurethane injection, while larger cracks may need more extensive repair or indicate that overlay isn’t appropriate.

Bonding Agents and Primers

Professional overlay installations use bonding agents or primers specifically designed to create strong adhesion between old and new concrete. These products are applied to the prepared surface immediately before pouring the overlay, creating a chemical and mechanical bond that prevents delamination.

Skipping this step—a mistake DIYers often make—dramatically increases the risk of overlay failure.

Minimum Thickness Requirements

While some speciality overlay products can be applied as thin as 1/4 inch, traditional concrete overlays should be at least 2 inches thick for exterior applications subject to traffic and weather. This minimum thickness provides adequate strength and durability. Thinner applications are more prone to cracking and delamination.

For areas subjected to vehicle traffic like driveways, 3-4 inches is preferable when possible. This provides the structural integrity needed to support the weight and stress of cars without failure.

Reinforcement Considerations

Thin overlays typically incorporate fiber mesh or wire reinforcement to prevent cracking. This reinforcement doesn’t prevent all cracks, but it helps distribute stress and keeps cracks tight if they do form. Proper reinforcement is essential for long-term overlay performance.

Alternative Solutions to Consider

Resurfacing Products

For surfaces with only cosmetic issues, specialised concrete resurfacing products offer another option. These polymer-modified toppings bond to existing concrete and provide a new wear surface at thicknesses from 1/8 to 1/2 inch. They’re less expensive than full overlays and work well for vertical surfaces, pool decks, and areas where minimal thickness is desired.

However, resurfacing products are less durable than structural concrete overlays and may not be appropriate for high-traffic areas or surfaces subjected to vehicle weight.

Complete Removal and Replacement

When existing concrete has significant structural problems, complete removal and replacement is often the most cost-effective long-term solution. While more expensive initially, replacement allows for proper base preparation, correction of drainage issues, updated thickness for current loads, and a fresh start with a full-thickness slab designed to last 30-40 years.

The cost difference between overlay and replacement narrows when you factor in the overlay’s shorter expected lifespan and the possibility of premature failure requiring complete replacement anyway.

Decorative Overlay Systems

If your primary goal is aesthetic improvement of structurally sound concrete, decorative overlay systems offer excellent options. Stamped overlays can mimic brick, stone, or tile at a fraction of the cost. Stained or dyed overlays create custom colours and patterns. These systems combine the practical benefits of concrete with the visual appeal of more expensive materials.

Making the Right Decision

Deciding whether to overlay existing concrete requiresan honest assessment of the existing surface’s condition, understanding of your goals and budget, consideration of how long you need the solution to last, and evaluation of alternatives.

Working with professionals at Courtney’s Construction ensures you receive an expert evaluation of your existing concrete, recommendations based on your specific situation and goals, proper installation if overlay is appropriate, and honest guidance when replacement is the better long-term choice. Experienced contractors won’t recommend an overlay when it’s likely to fail—they understand that their reputation depends on providing solutions that perform well for years to come.

Concrete overlays can be excellent solutions in the right circumstances, but they’re not universal fixes for all concrete problems. Understanding the limitations and requirements helps you make informed decisions that provide the best value and longest-lasting results.