Buying the right water transfer pump in 2025 requires more than just picking a model off the shelf. The wide range of options can make the process feel overwhelming, but a clear understanding of key factors helps narrow the choice. Choosing the right pump saves time, reduces costs, and makes the job far more efficient.

This article outlines the main considerations that guide a smart purchase, from performance features to long-term operating costs. By looking at the most important aspects step by step, anyone can feel more confident about selecting a pump that matches their specific needs.

Flow Rate and Volume Capacity

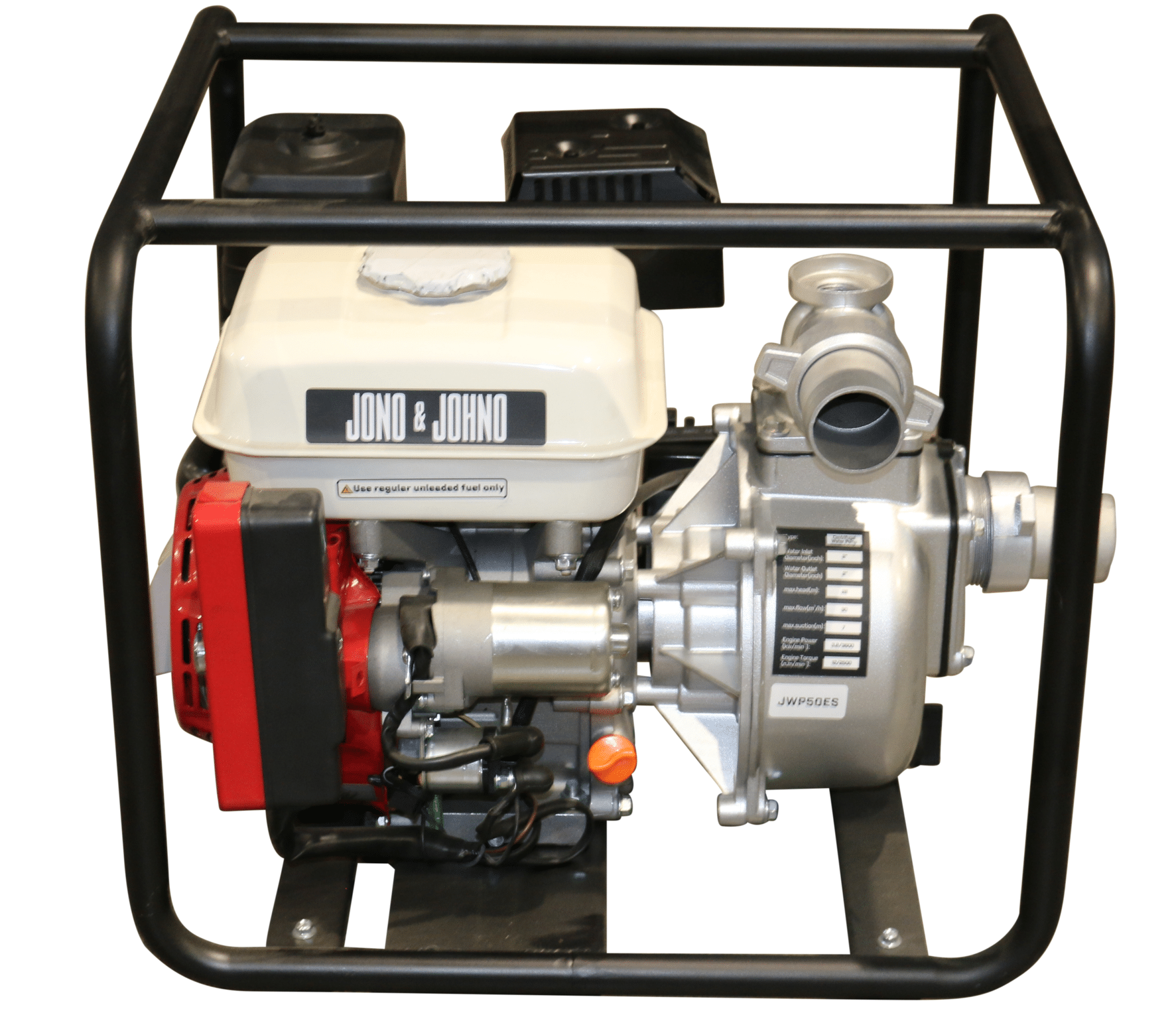

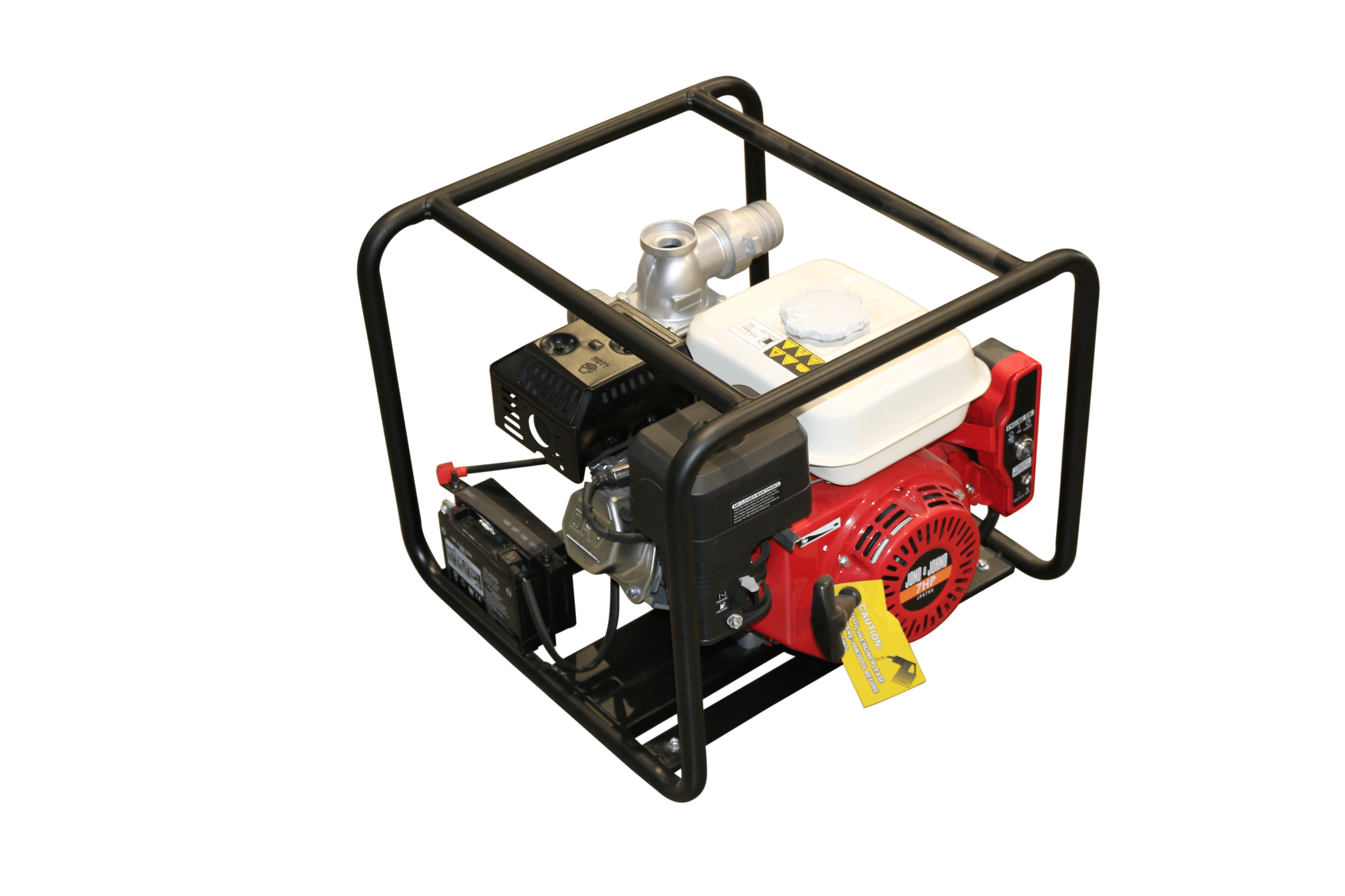

Flow rate measures the volume of water a pump can move in a set time, typically in litres per minute. A higher flow rate allows for faster transfer, which is particularly suitable for tasks such as emptying tanks or moving water over short distances. Lower flow rates may be sufficient for smaller jobs, such as gardening.

Volume capacity refers to the total amount of water the pump can handle during operation. This factor matters for large-scale tasks, such as draining a pool or supplying water to a farm. Matching the pump’s capacity with the job prevents delays and reduces strain on the equipment.

Different applications require different combinations of flow rate and capacity. For example, a submersible pump may handle steady flow for long periods, while a petrol-driven unit may deliver higher volumes quickly. Buyers should compare specifications before making a choice.

Those looking for water transfer pumps from sources like: https://www.chainsawspares.com.au/ebay-store-3/water-pumps-hoses-fittings/transfer-pumps/ can find models with varied flow rates and capacities. Selecting the right type helps achieve efficient water movement without overspending on unnecessary power.

Maximum Head Height

Maximum head height refers to the highest level a pump can push water from its source to the outlet point. It is usually measured in metres and shows the maximum vertical distance the pump can move water.

This factor is important because it determines whether the pump can handle elevation changes or long pipe runs. A pump with a low head height may struggle to deliver water to higher ground or through long piping systems.

Manufacturers often list both maximum head and rated head. Maximum head represents the absolute limit, while rated head gives a more practical measure of performance. Buyers should consider the rated head for real-world use, as pumps rarely operate well at their maximum figure.

For example, a pump with a maximum head of 40 metres may only provide steady flow up to 30 metres. Therefore, it is important to match the pump’s head height to the actual site requirements rather than relying on the highest number shown.

Power Source Compatibility

The power source of a water transfer pump directly affects how and where it can be used. Electric pumps are suitable for homes or sites with steady access to mains power, while petrol or diesel pumps are more effective in remote areas without electricity.

Each option has trade-offs. Electric pumps usually run more quietly and require less upkeep, but they depend on a nearby outlet. Fuel-powered pumps provide more mobility and higher output, though they need regular refuelling and produce emissions.

Battery-powered models have become more common in 2025. They offer portability and easy setup, but run times remain shorter compared to fuel or mains-powered units. Therefore, users must weigh convenience against operating limits.

Environmental conditions also influence the best choice. For example, farms or construction sites often prefer fuel pumps due to their strength and independence from power lines. In contrast, households benefit from electric pumps that connect directly to existing wiring.

Selecting the right power source helps match the pump’s performance to the specific task and location.

Durability and Maintenance Requirements

A water transfer pump must handle frequent use without constant breakdowns. Buyers should check the build quality of the housing, seals, and impeller, as these parts face the most stress. Stronger materials often last longer and reduce the chance of leaks or cracks.

Ease of maintenance also affects long-term performance. Pumps with accessible parts allow quick inspections and simple part replacement. This design reduces downtime and keeps the pump in service for longer periods.

Manufacturers usually provide maintenance schedules that outline service intervals. Following these guidelines helps prevent unexpected failures and keeps efficiency steady. Regular checks on oil levels, filters, and seals make a noticeable difference in lifespan.

Durability also connects to the type of water being moved. For example, pumps that handle dirty or abrasive water need tougher components compared to those used for clean water. Matching the pump’s design to the intended application prevents damage and cuts repair costs.

Energy Efficiency and Operating Costs

Energy use plays a major role in the long-term cost of a water transfer pump. A model with lower power demand can reduce electricity bills, especially for households or farms that use the pump often. Therefore, it makes sense to compare the energy ratings of different units before purchase.

Operating costs go beyond electricity. Maintenance, spare parts, and service fees also add up over time. A pump with fewer moving parts may need less upkeep, which can save money in the long run.

Low-pressure pumps often consume less energy than high-pressure pumps. However, they may not suit every application. Buyers need to balance power with efficiency to avoid higher bills or poor performance.

It is also important to think about how often the pump will be used. Occasional use may make energy efficiency less important, but frequent use can quickly increase costs. Choosing the right balance helps keep both performance and expenses under control.

Conclusion

A water transfer pump purchase depends on matching the pump’s features to the task. Flow rate, pressure, power source, durability, and ease of use all shape how well the pump performs in real conditions.

Each factor matters differently depending on whether the pump is for home, farm, or industrial use. Therefore, buyers should weigh their needs against these points before making a choice.

By focusing on these five areas, buyers can select a pump that meets current demands and also supports future needs. This approach helps them make a practical and cost-effective decision.